Categorías

Nuevo blog

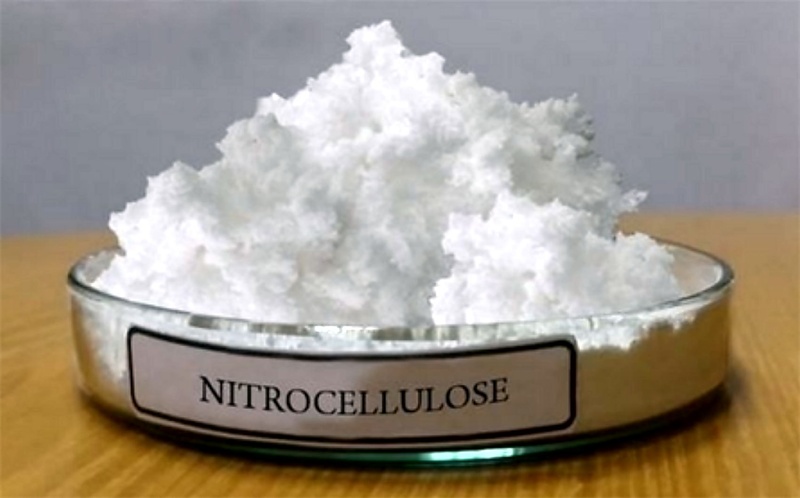

Nitrocelulosa: un material versátil entre la munición y la tinta

Jan 15, 2026

La nitrocelulosa (NC), un derivado versátil de la celulosa sintetizado mediante la nitración de fibras de celulosa con una mezcla de ácidos nítrico y sulfúrico, ocupa una posición única y crucial en dos industrias globales aparentemente dispares: la fabricación de defensa y la impresión comercial. En aplicaciones militares, la NC es un componente fundamental en la producción de propulsores sin humo, explosivos y cargas de proyectiles de artillería, valorada por su alta densidad energética y propiedades de combustión controlables. Por otro lado, en el ámbito industrial, la NC actúa como un aglutinante indispensable en formulaciones de tintas y recubrimientos a base de solventes, especialmente para procesos de impresión flexográfica y huecograbado. Su excepcional capacidad para facilitar la rápida evaporación del solvente garantiza tiempos de secado rápidos, excelente claridad de impresión, fuerte adhesión al sustrato y un acabado de alto brillo, lo que la convierte en el material predilecto para la producción a alta velocidad de empaques flexibles, etiquetas y diversos productos laminados.

El pivote geopolítico: creciente demanda militar y escasez industrial

El panorama geopolítico actual, caracterizado por conflictos prolongados como la guerra en Ucrania y una mayor preparación en materia de seguridad entre los Estados miembros de la OTAN y la UE, ha provocado un aumento sustancial y sostenido del gasto mundial en defensa. Esto, a su vez, ha precipitado un drástico aumento de la demanda de nitrocelulosa de grado militar. En respuesta, los productores de CN están reasignando estratégicamente sus capacidades de fabricación y cadenas de suministro para priorizar los pedidos de municiones y materiales explosivos. Este cambio estratégico se ejemplifica en importantes maniobras corporativas dentro de la base de suministro, incluyendo la adquisición de productores especializados de CN por parte de contratistas de defensa.

La consecuencia directa de esta desviación de la oferta es una rápida restricción del mercado de NC de grado industrial, lo que genera graves dificultades de adquisición y una inflación de costes sin precedentes para los usuarios finales en los sectores de la impresión y el embalaje. Los análisis de mercado indican que los precios del NC han aumentado más del 50 % en regiones clave desde mediados de 2024. Esta aguda presión de costes ha obligado a los principales fabricantes internacionales de tintas, como Sun Chemical, Flint Group y Hubergroup, a implementar sucesivos aumentos de precios en sus carteras de productos que contienen NC. La situación se ve agravada por las complejidades logísticas y las restricciones regulatorias existentes en torno al transporte y almacenamiento de NC, lo que crea una situación ideal de disrupción en la cadena de suministro para las industrias civiles.

El papel irremplazable del control numérico en la impresión moderna

La dependencia de la nitrocelulosa en la industria de la impresión se basa en su inigualable rendimiento. Como principal agente formador de película en tintas a base de solventes, el NC permite eficiencias operativas cruciales. Su rápida liberación del solvente es fundamental para lograr altas velocidades de impresión en la impresión flexográfica y de huecograbado, tecnologías dominantes para la producción de envases de alimentos, etiquetas de productos de consumo y materiales promocionales. Además, las tintas a base de NC proporcionan una excepcional resistencia de adhesión a una amplia gama de sustratos, incluyendo películas de poliolefina tratadas, poliéster y superficies metalizadas, a la vez que ofrecen la intensidad de color uniforme y las superficies duraderas y de alto brillo que las marcas y los consumidores esperan. Esta combinación de atributos funcionales ha convertido a las formulaciones a base de NC en un pilar de la impresión de envases durante décadas. Sin embargo, la naturaleza de "doble uso" del NC, que en su día demostró su versatilidad, se ha convertido en una vulnerabilidad significativa, condicionando la estabilidad del suministro del sector de la impresión comercial a los ritmos volátiles de las compras globales de defensa.

Innovación bajo presión: el auge de las alternativas de alto rendimiento sin CN

Ante la persistente inseguridad del suministro y el aumento de los costos, los formuladores de tintas y las empresas químicas están intensificando sus esfuerzos de investigación, desarrollo y comercialización para encontrar alternativas viables sin NC. El objetivo es diseñar sistemas de tinta de nueva generación que igualen o superen los estándares de rendimiento de los productos tradicionales basados en NC, eliminando al mismo tiempo la dependencia de esta materia prima tan controvertida. Las alternativas más avanzadas y de mayor éxito comercial se basan en resinas de poliuretano (PU) de alta química. Empresas como INX International, Flint Group y Siegwerk han lanzado series completas de tintas flexográficas y de huecograbado basadas en PU, como la serie Innova Plus NCF de INX y la plataforma Vertix® de Flint, que replican con éxito las características de secado rápido, adhesión y rendimiento de sus predecesoras NC.

Más allá de la simple sustitución de una materia prima, esta transición se está aprovechando para impulsar objetivos de sostenibilidad más amplios dentro de la cadena de valor del embalaje. Los sistemas modernos de tinta sin CN suelen diseñarse con una reciclabilidad mejorada, en particular apoyando el reciclaje mecánico de películas de plástico al mejorar las características de lavado de los materiales impresos. Esto se alinea estratégicamente con estrictos marcos regulatorios como el Reglamento de Envases y Residuos de Envases (PPWR) de la Unión Europea, que exige un mayor uso de contenido reciclado y promueve el diseño para la reciclabilidad. Por lo tanto, la transición a formulaciones sin CN se considera cada vez más no solo un plan de contingencia para la cadena de suministro, sino un paso hacia una mayor circularidad y cumplimiento ambiental.